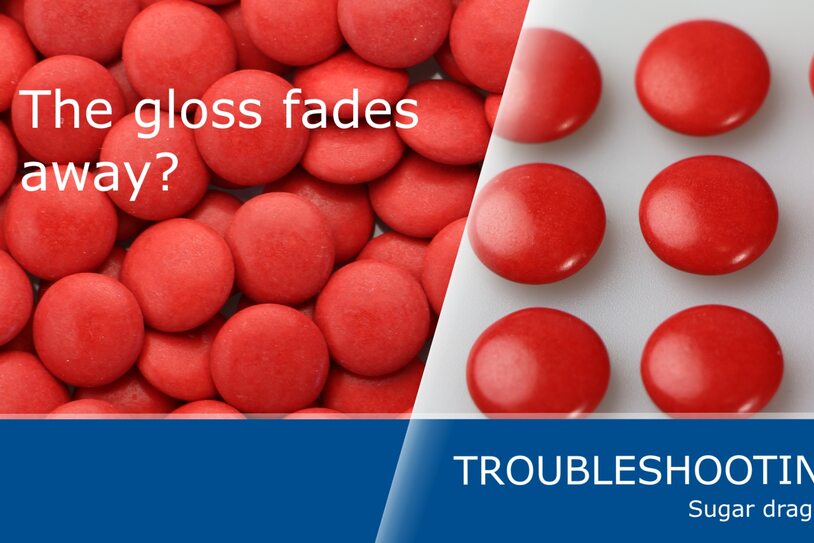

You do not get a second chance at a first impression. The well-meaning advice we all know from everyday life is also true for your candy. But what to do when the hard-earned gloss of your sugar dragées fades away? CAPOL® Application Technology helps with troubleshooting advice.

Best ingredients, refined recipes and a glossy finish - Confectioners pay attention to every detail to bring the perfect product to the shelf. Brightness of colors and the first overall impression are a crucial factor in the consumers’ decision for their favorite candy. What a shame when the hard-earned gloss of the sugar candy fades away and the visual appeal gets impaired. CAPOL® Application Technologist Dr. Valeria Reim knows that fading of gloss with hard and soft sugar dragées can pose a serious risk for producing the best appearing candies. She is a PhD Nutritional Science and works with CAPOL® customers worldwide to help them achieve best results in their confectionery finishing and efficiency of their processes. Valeria knows the factors that can be helpful in a first approach to troubleshooting.

You took everything into account during manufacturing of the confectionery … applied the correct dosage of a CAPOL® product … but the gloss disappears sometime after polishing? What happened? “One possibility might be that the centers are not dried adequately before polishing”, explains Valeria, “The trapped moisture in the sugar shell will react with the ingredients of the polishing agent, which finally impairs the gloss.” She recommends as a golden rule: Sufficiently dry your centers before using a polishing agent.

The manufacturing and transportation environment can be another reason for gloss fading. If centers are, say, exposed to high relative humidity, this can have undesired effects on the finish. “Sugar is known to be hygroscopic, which means it takes up the moisture from the air or surrounding environment”, says Valeria. “It sometimes happens that the polished centers absorb the moisture from the ambient air and become dull.” As a remedy, Valeria suggests strict adjustment of the production settings or use of airtight packaging. Valeria goes on to explain that, “often the required conditions are hard or impossible to implement in an existing manufacturing plant. Applying a sealing agent based on shellac, like CAPOL® 425M, will protect the gloss from damages due to fluctuations in environmental conditions.”

If you face troubles with the polishing of your hard or soft sugar confections, get in touch with our CAPOL® Application Technology team. We know from experience that all candy and manufacturing conditions have their own challenges. This is why we deliver more than a ready-to-use product, but also support you with our service and expertise along the entire product development process, from the beginning to the perfect CAPOL® finish.