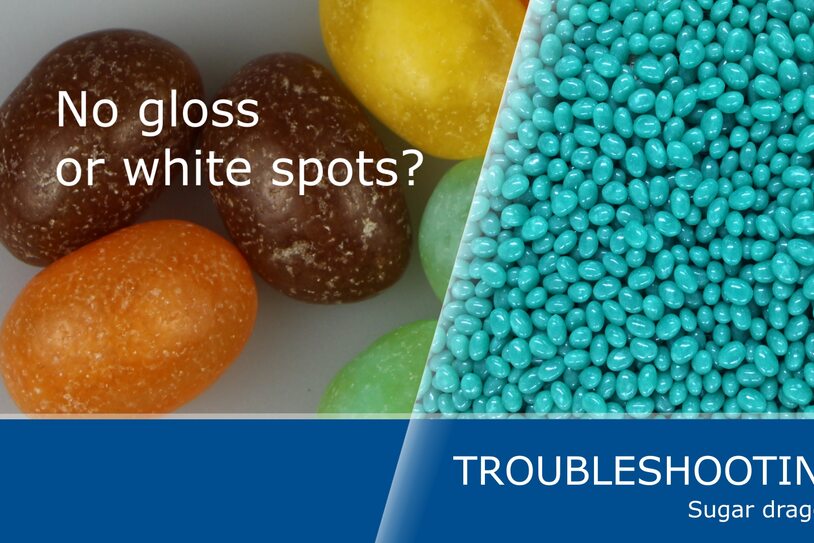

The eyes eat first! No matter if hard sugar coated lentils or soft sugar coated jelly beans, only an attractive piece of a candy will find its way to the mouth of both, small and big sweet tooth. That is why a dull surface or white spots can be a serious problem in confectionery manufacturing.

What should you consider when you want to produce the perfect candy? How do you create a picture-perfect gloss? CAPOL® polishing and glazing agents take care of large parts of this work for you. Applied at the end of the manufacturing process, they create a brilliant shining surface for both soft and hard sugar dragées. Nevertheless, some precautions must be taken into account beforehand to create the perfect finish. “It is important to master the craft, both in manufacturing and the surface treatment of confections”, says Dr. Valeria Reim, CAPOL® Application Technologist. For more than three years, she has worked with candy manufacturers around the world and knows the pitfalls of confectionery finishing.

“To avoid poor results it is important to understand what gloss is and how it is created”, Valeria says. “Gloss is defined as the ratio of the incoming and the reflected light on a surface of an object. The more even a surface, the higher is the amount of specular reflection. Likewise, the rougher a surface the lower is the amount of specular light reflection and the higher the amount of diffuse light reflection that gives you an impression of dullness.”

So, what to do if you encounter a problem of “no gloss” or “white specks” on the surface of your sugar dragées? Why does this occur? Application Technologist Valeria points out: “Before starting to polish hard or soft sugar coated centers, you have to make sure that the surface is fully solidified and dry, and more importantly smooth and dust-free! Dust, or sugar crystals to be more precise, act similarly to sand paper and will rub off the wax particles and therefore the shine.” All surfaces need to be smooth and dust free, this does not only go for your candy but also the equipment you are using, e.g. conventional pan.

Valeria has specific recommendations for both hard and soft sugar dragée manufacturing: “As for hard sugar coated centers, end up the coating process by drying the centers in a rotating pan without applying process air. Afterwards, the centers can be stored in perforated trays overnight to reach the optimum residual moisture in the coating.” For soft sugar coated centers, attention needs to be payed to the fact that not too much icing (confectioners) sugar or specialized product like FIX GUM B® is used at the end for smoothening of the surface. Otherwise, the sugar solution used prior to polishing cannot bind the residual sugar dust.

What to do if you have followed all the instructions, but still there is no gloss? “Well, applying the correct dosage of the surface treatment product is crucial in achieving the perfect finish. The often quoted ’More is better’ does not always apply”, Valeria knows from troubleshooting experience. The dosage needs to be adapted to the type, shape and size of the centers as well as to the CAPOL® polishing agent itself. “We provide technical leaflets or application sheets so you know exactly how to use a product in your manufacturing process. But we know that every candy and production routine has its own challenges, so our CAPOL® Technical Sales team is happy to provide personal and customized assistance”, Valeria points out.

White spots can often be traced back to a dragée surface that was not smooth enough to start the polishing process. An irregular surface is impossible to be polished with wax-based systems, like CAPOL® 600 (hard sugar) or CAPOL® 5186 in combination with CAPOL® 1400 (soft sugar). As Valeria explains: “The irregularities on the surface will entrap the wax particles while the shine stays off. Instead, white spots become noticeable.” Additionally, she points to another trouble shooting approach: “A different reason white spots may occur could be related to the coating process itself. Prolonged drying cycles will trigger the sugar re-crystallization.” This accelerates the building up of white spots (sugar crystals) beneath the glossy layer during the polishing process.

If you need assistance in your jelly beans, sugar lentils or other candy polishing process, get in touch with our CAPOL® Application Technology Team. We are your application expert for surface treatment in the confectionery industry.